When a fire pump is running at churn (no flow), there must be some water discharging in order to keep the pump, packing, and bearings cool. When there is no water moving at all, the amount of horsepower transfers energy in the form of heat into the water.

Casing relief valves (CRVs), are a critical component on all electric fire pump installations. They are also a potential source of call backs during the contractor’s warranty period. Understanding how they function and how to protect them from damaging misapplication can save you time and money. Here are the main things to know:

1) The CRV is a pressure relief valve, not a flow control.

2) The sealing surfaces of a CRV will rapidly wear and fail if the pressure differential and velocity across the valve is too high. Using the CRV to regulate flow increases velocity. Velocity is the seat killer.

A CRV is generally not able to reliably open, close, and also throttle the discharge to an acceptable rate of flow. Anytime the CRV is used to control discharge flow so as to not overwhelm the drain, the opening set point of the CRV will be slightly above the churn pressure of the pump. If the water supply is from a pressurized main and the suction pressure drops then the discharge pressure also drops. This often leads to a situation where there is not enough pressure to open the CRV, placing the pump in danger.

Additionally, using the CRV to control flow increases the pressure differential across the seat of the CRV, leading to rapid wear and early failure.

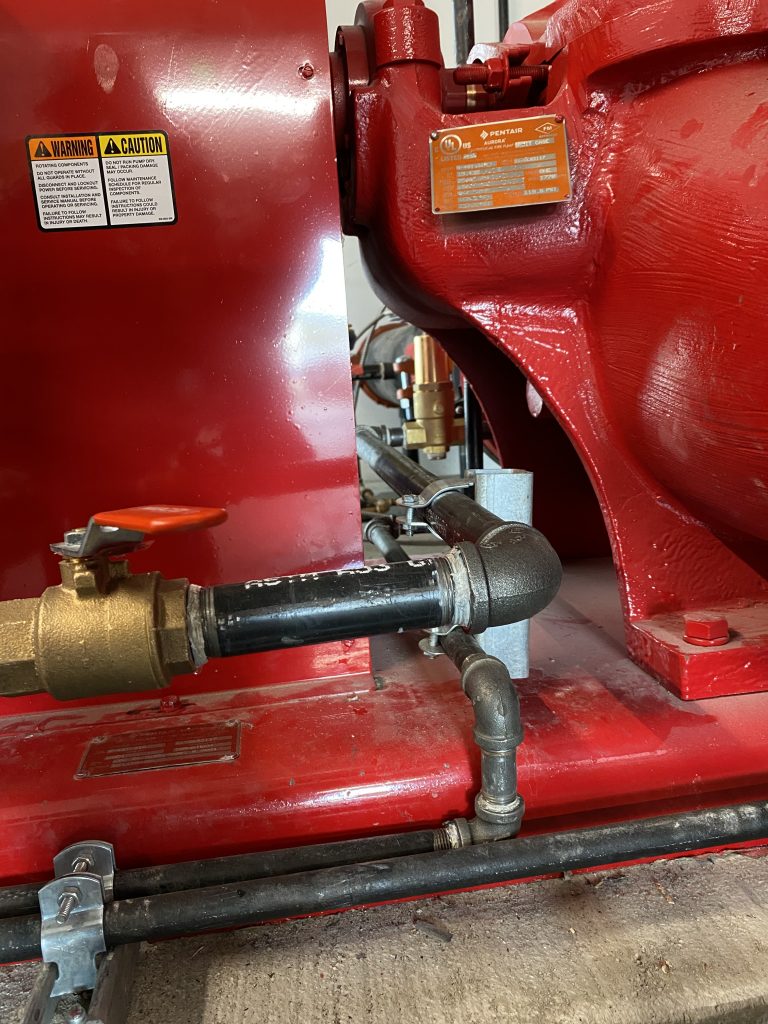

In order to assure that the CRV will reliably open and also close without leaking it’s best set the CRV to open well below the churn pressure of the pump. Then install a ball or gate valve down stream of the CRV and dial in the required rate of discharge flow with that valve. (Make sure to remove the handle on the throttling valve to avoid it being tampered with after it is correctly adjusted.) You can then do a bucket test on the CRV discharge and replace the ball or gate valve with a properly selected Dole Flow Control. (cannot be tampered with)

All of this accomplishes two important things: First, the CRV now has a wide margin to reliably open, even if suction pressure drops and/or pump performance degrades over time. Second, the CRV now has backpressure downstream of the seat, greatly reducing the differential pressure (and therefore velocity) across the seat of the valve ensuring long seat life of the CRV. The CRV will now reliably open, close drip tight when the pump is not running, and last much longer before having to be replaced.